Products

What is the difference between the CRAC tube and the corrugated tube and the hollow tube produced by the carat tube equipment?

Contrast of molding process

1, carat tube forming process:

Clark tube is extruded by the main extruder, U-shaped belt extruded by the sub-extruder and wrapped with PP skeleton tube winding on the mold. It is continuously monitored and controlled by computer during the whole production process, and cooled by rolling natural wind. The carat tube is a hot melt winding process.

2, HDPE double wall bellows molding process:

HDPE double wall bellows are pipes that are directly extruded through two concentric tube embryos and are molded by suction. It is an extrusion process.

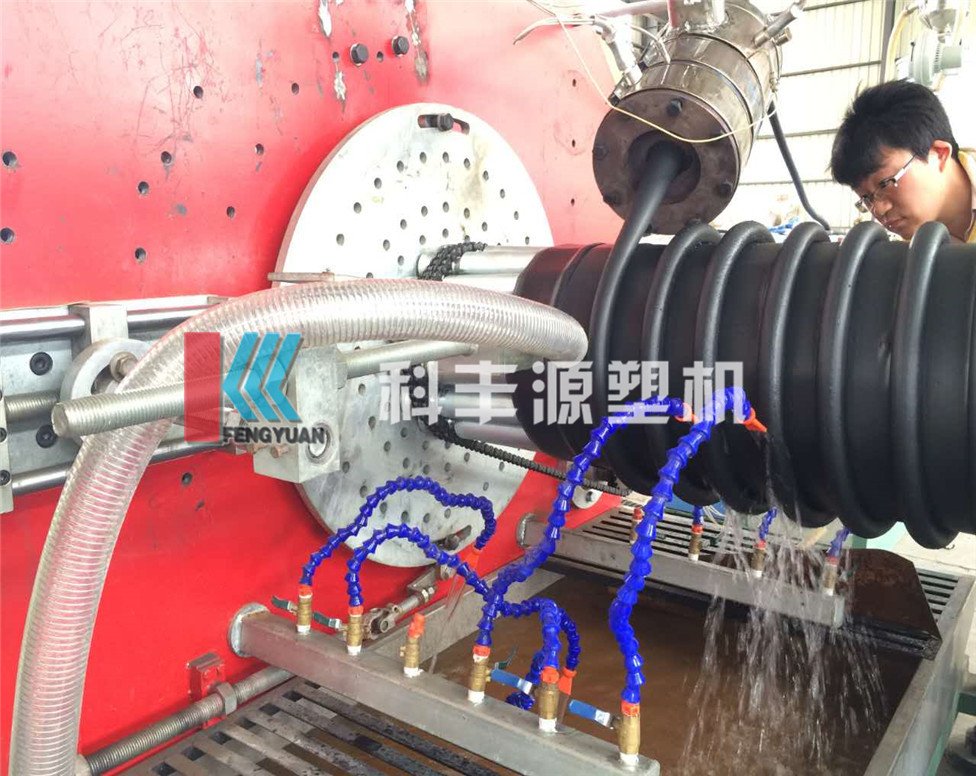

3. HDPE hollow wall tube forming process:

HDPE hollow wall tube is completed by two extruders. The main extruder extrudes the tube into a square tube after vacuum setting and water cooling. Then the square tube is wound to the molding machine. At the same time, the auxiliary extruder extrudes the auxiliary material and fills the gap. During the welding process, water cooling must be used continuously to keep the tube embryo from happening. Heated deformation.

Comparison of process and structure characteristics

1. Technology and structure characteristics of carat tube

1) adopt hot winding and natural wind rolling cooling, the structure wall has no internal stress and no weld. The wall thickness of the pipe is uniform.

2) The expansion coefficient of polyethylene material is large. When the expansion and cold shrinkage occur, the outer ribbed pipe and backfill soil act together, which will effectively restrain the longitudinal displacement of the pipeline system, prevent the stress concentration at both ends of the pipeline, and destroy the connection with the inspection well.

2, HDPE double wall bellows technology and structural characteristics:

1) extrusion is adopted, and the appearance of pipes is better.

2) the length of 12m pipe can be produced.

3, HDPE hollow wall tube technology and structural characteristics:

1) There are stresses in the wall of the structure by winding and water cooling, and there are hidden dangers in actual use.

2) in cold welding, the weld length is long and the weld quality is difficult to guarantee.

3) The outer wall is smooth, which can not effectively restrain the longitudinal displacement caused by the thermal expansion and cold contraction of PE material. It often causes stress concentration at both ends of the pipeline, and destroys the connection between the joint or the pipeline and the inspection well, resulting in water leakage.

4) the maximum ring stiffness is 8 KN/m2.

4, UPVC double wall bellows technology and structural characteristics:

1) extrusion is adopted, and the appearance of pipes is better.

2) the length of 12m pipe can be produced.

3) Influenced by the process equipment and the melt flow rate of UPVC material, the diameter of the pipe produced is small, mainly producing DN500mm pipes.

4) The ring stiffness of UPVC double-walled bellows is much lower than that of the wall tubes of the winding B-type structure, which mainly consists of S1 and S2.

Pipe diameter contrast:

1, the caliber of the carat tube is DN300mm-DN4000mm

2. HDPE double-wall corrugated pipe caliber: mainly produces DN 600 mm below the pipe, a small number of domestic manufacturers can produce DN 1200 mm below the pipe, but the actual application is not many.

3. The diameter of HDPE hollow wall tube is below DN3000mm.

4, UPVC double wall bellows tube diameter: DN500 below.

Qingdao Kefengyuan Plastic Machinery Co., Ltd. has developed more than 20 new products, such as environmentally friendly PP super-thick plate production line, PVC wood-plastic plate production line, PE large-caliber gas/water supply pipe production line, PE large-caliber hollow wall winding pipe production line, PP-R pipe unit, plastic buckler unit and so on. The Middle East, Africa and many other countries and regions.

Top